Understand the Use of Tube Suppression Systems for Fire Diffusal

Fire safety is a critical concern in practically all industries, from manufacturing facilities to data centers and even mundane applications like kitchens and vehicles. Tube suppression systems have gained interest among all types of fire suppression technology for their simplicity, efficiency, and reliability. In this blog, we shall discuss the main features, advantages, and applications of tube-based suppression systems, specifically in-panel systems and automatic fire detection tube suppression systems.

A Guide to Tube Suppression System Do

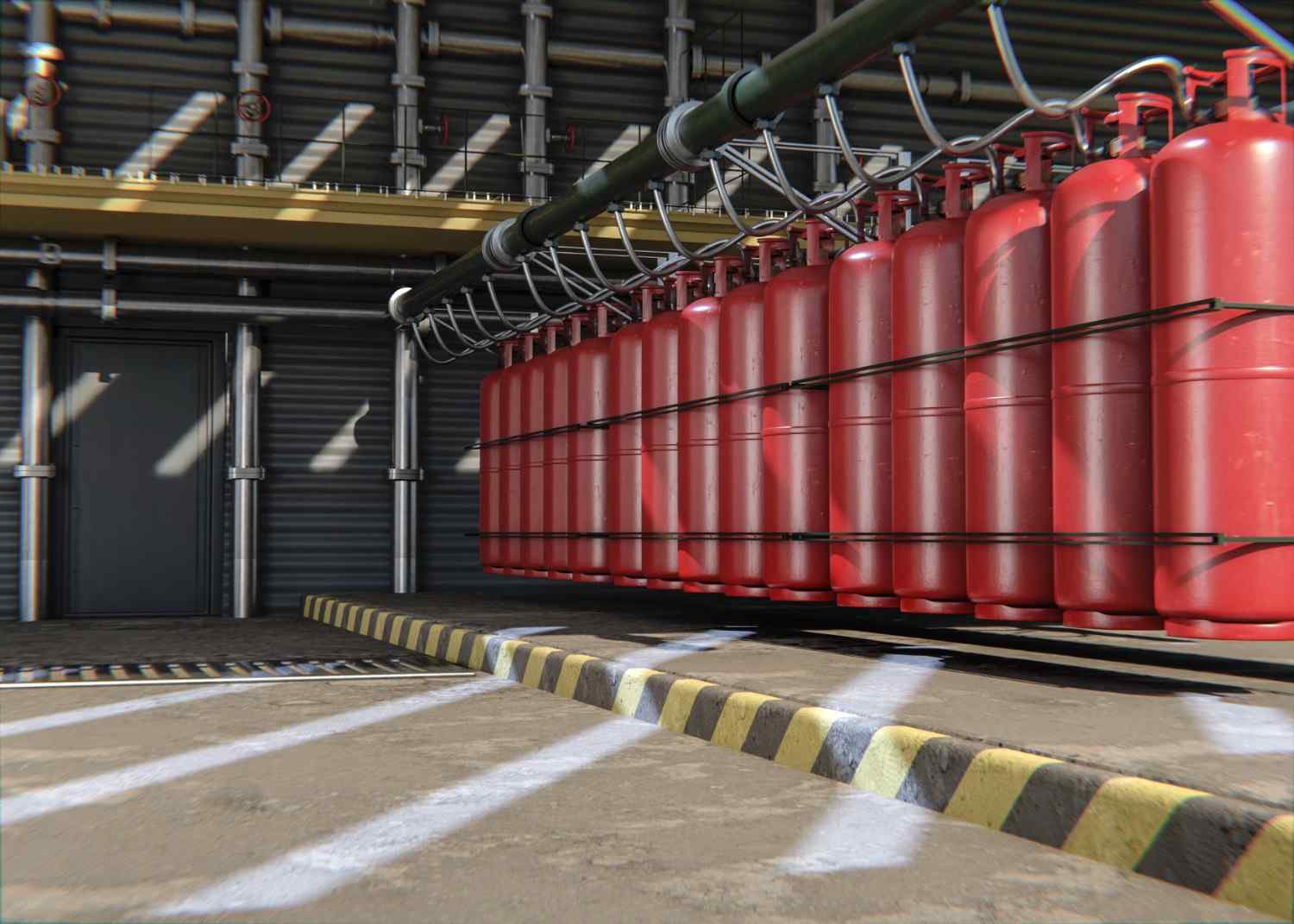

A tube suppression system is a fire detection and suppression system that affords rapid detection and extinguishment of fire at its source. It is ultimately a flexible, heat-sensitive detection tube that serves the dual purpose of actuating and delivering the extinguishing agent. The tube is placed inside protected areas or areas prone to fire, such as electrical panels, machine enclosures, or confined spaces.

When high heat or flames come into contact with the tube, it ruptures at the hottest exposure point, delivering the required extinguishing agent directly onto the fire. Our extinguishers are less prone to damage and maintenance.

How Does In-Panel Tube-Based Suppression Systems Work in Tough Situations?

Spectra Fire’s in-panel tube-based suppression system is designed to protect people and infrastructure. The costs associated with downtime and equipment loss from fire damage can be quite high, especially for expensive and sensitive components mounted on the electrical and control panels.

Main Characteristics of In- Panel Tube Based Suppression Systems

Timely Use and Application: Find a path inside the panel, allowing for maximum rapid detection and suppression right at the ignition’s source.

Space Constraints and May Fit Small Places: Ideal for small spaces where conventional fire suppression systems may not fit.

Technical and Non-Conductive Agents at the Fire Extinguisher: They are filled with clean agents such as FM-200 or Novec 1230. And are safe for electronics.

Affordable and Low Maintenance: Our products are safe to use, have a simple design and have fewer components.

Avail the Benefits of In-Panel Tube-Based Suppression Systems

Fast Action Ability: It can detect fire in a few seconds at the hazard.

Low Downfall (Damage) Components: It will not damage sensitive electronic components.

Affordable to Replace and Repair: Takes care of high-value equipment for a fraction of the cost of replacing the equipment.

Usage and Applications of the In-Panel Tube

- Protect critical IT infrastructure.

- Protects important communication equipment and tools.

- It protects hospitals and laboratories from fire.

A Guide to Understand How Automatic Fire Detection Tube Suppression Systems Works

Our automatic fire detection tube suppression systems work wonderfully as it is versatile in use. This system is excellent at working and reducing fire with fire suppression.

- Principles of Automatic Fire Detection Tube Suppression System

- A pressurized detection tube filled with an extinguishing agent.

- When a fire occurs, the heat causes the highest point of the tube to burst.

- The extinguishing agent is released straight onto the flame and extinguishes it most quickly.

What Are the Different Uses and Applications of Automatic Fire Detection Tube?

- Automobiles: It is used in the automobile industry for fire safety in engine compartments to prevent fast fire development.

- Kitchens: It protects stove or fryer areas when it’s prone to fire occurrences.

- Industrial Equipment: It works great for CNC machines, welding enclosures, and other environments.

- Marine vessels: Fire safety in engine rooms and hidden compartments on boats and ships.

- Renewable Energy Systems: Protection of the battery storage units and solar panel inverters.

Several Advantages of Automatic Fire Detection Tube

- Automatic activation: Workers would not need to use their hands to detect or put out a fire.

- Localized suppression: The aim is to put out the fire as it develops for minimal use of the extinguishing agent.

- Eco-friendly: Many systems use environment-friendly agents that do not leave a residue.

- Easy to install: Installation can be done in new and already existing arrangements without too many modifications.

Tube Suppression Systems: Important Keys

- Effectiveness: Fast response means little loss of time and extent of damage.

- Versatility: Can work across environments, including industrial, commercial, and even residential.

- Low-Cost: Quick installation and maintenance at a much lower cost than traditional suppression systems.

- Reliability: A simpler design with fewer components allows for fewer chances of malfunction.

- Scalability: Down-scaling of components allows circulation to be designed for many systems, with their various sizes and complexities.

Considerations to Keep at Finger Tips

- Fire Risk Assessment: Conduct a complete analysis of areas susceptible to fire raging inside them for the perfect positioning of the detection tubes.

- Agent Selection: Choose the extinguishing agent which is befitting for placement; eg: clean agents- type for electrical systems or wet chemicals for kitchens.

- Routine Maintenance: Regular tests to check pressure loss and displacement invalidation of liquefied agents on the detection tubes show consistency.

- Code Compliance: This is to confirm that our product is easy to install as per the authority’s respective fire safety codes.

- Training: We also train people to use our product to face tough situations in fire.

Conclusion

Tube suppression systems are one of the best products used in fire safety. Whether you’re protecting electrical panels, industrial machines, or vehicles, these systems win the day based on speed, simplicity, and efficiency. Installing a tube system means securing equipment, personnel, and your operations.

For further information, you can contact us right away and avail the information regarding our products.